Downhole multistage pump Pedrollo 4SR4m/18P with control panel

Availability: In stock

Downhole multistage pump Pedrollo 4SR4m/18P with control panel

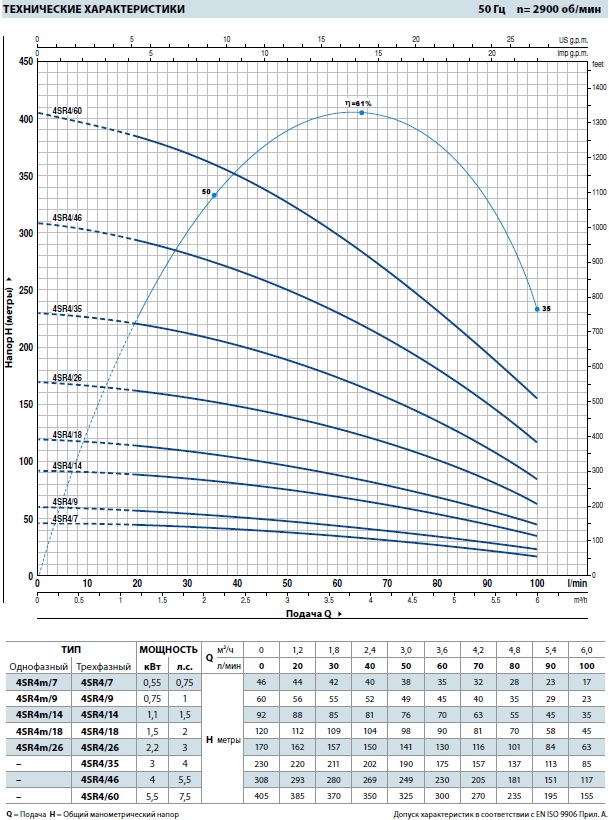

Brief technical characteristics

- flow up to 100 l/min. (6.0 m3 /h)

- head up to 170 m

- maximum liquid temperature up to +30°С

- maximum sand content: 150 g/ m3

- number of starts: max. 20/hour

The special patented design of the hydraulic part of the pump, the combination of materials used and the front insert with axial movement of the impellers provide reliable protection of the pump against sand and jamming.

Principle of operation

The 4SR4 series includes multistage centrifugal type electric pumps designed for permanent submerged operation.

The motor is connected to the pump through a caliper, the parameters of which comply with NEMA standards. The principle of operation is similar to that of multistage centrifugal pumps. The impellers, mounted on the same drive shaft, rotate inside the vaned diffusers, which move the fluid at the outlet of each impeller towards the suction port of the next impeller. After passing through all the impellers installed in series, the liquid leaves the pump through the discharge pipe. Each impeller with a corresponding vaned diffuser creates a discharge stage which, according to the principle of operation of centrifugal pumps, provides the liquid with a pressure drop that is added to equal pressure drops created by other successive stages.

Scope and installation

Pumps of this series are recommended for pumping clean water or liquid bodies containing no more than 150 g/m3 of sand. Due to their high efficiency and their reliability, these pumps are used in everyday life, in industry, for automatic water supply in conjunction with automatic pressure maintenance units, for irrigation of vegetable gardens and orchards, for washing equipment, for increasing pressure and in fire safety systems, etc. Operation of the 4SR4 pumps is possible inside wells with a diameter of at least 4" (100 mm). The electric pump is lowered into the well by means of a discharge pipeline to a depth at which it is completely immersed (min. 50 cm and not less than 1 meter to the bottom of the well), even in the pump can be installed both vertically and horizontally: when the pump is installed vertically inside the well, it is recommended to use a stainless steel or nylon cable through the holes as a precaution provided in the pressure housing.

Structural features

- Discharge body made of brass OT 58, equipped with a discharge connection with pipe thread 1 1/4" gas UNI 338.

- The non-return valve in technopolymer, of increased strength, allows the weight of the water column to be relieved without stressing the impellers and diffusers, thus ensuring maximum durability.

- Lexan® "General Electric®" technopolymer impellers.

- Diffusers in Noryl® GFN2 technopolymer.

- Diffuser carrier in AISI 304 stainless steel.

- AISI 304 stainless steel pump jacket.

- Drive shaft in AISI 304 stainless steel.

- Brass caliper with NEMA specifications.

- Traction coupling made of agglomerated stainless steel AISI 316L.

- AISI 304 stainless steel filter.

- Submersible motor, 4" "Franklin Electric®" in water bath or "PEDROLLO" rewindable in oil bath.

- Degree of protection IP 58.

- Submersible power cable made of neoprene "H07-RN-F". Standard equipment 1.5 m.

|