Modular transportable boiler plant MTKU-0.5T(V) with a capacity of 0.5 MW

Availability: Out of stock

Modular transportable boiler plant MTKU-0.5T(V) with a capacity of 0.5 MW

Modular transportable boiler plants MTKU-(V) are designed for heating water in heating and hot water supply systems with a heating temperature of up to 115 ° C. Boilers are produced in a wide range of capacities from 100 kW to 9.0 MW. Our boiler plants do not require project development , as they are manufactured according to the specifications of TU U 25.3-36350685-001:2014 , as a finished factory product and have a certificate of conformity of Ukraine UA. TR. 089.02223-14. For the installation of a boiler house, it is only necessary to develop a "installation on site" project.

MTKU are manufactured taking into account all the wishes of the Customer in terms of configuration (boilers, burners, pumping equipment, fittings, etc.), equipment placement and outlets of connecting pipelines.

Main advantages:

- it is not required to develop a full-fledged boiler house project, which increases the cost and construction time. It is only necessary to complete the project for supplying external communications;

- if necessary, the boiler room can be easily transferred to another facility;

- low payback periods;

- small overall dimensions;

- the ability to start immediately after installation.

Types of fuel burned:

- auto-feed: small-fraction fuel in the form of pellets from different types of wood, peat, sunflower seed husks, as well as meal, rapeseed fuse, wood chips, sawdust, straw, etc.

- manual loading: firewood, coal, peat briquettes, packaged straw and other coarse fuel.

At the choice of the Customer, hot water boilers of both domestic and European manufacturers can be installed in the boiler room.

The boiler room is delivered to the installation site in transportable blocks and after installation it is a single room with the main and auxiliary equipment installed. Additionally, heat points with collapsible plate heat exchangers for heating individual branches of the heating system and hot water supply can be located in the boiler room.

Delivery set includes:

- boiler room on the basis of metal structures (boxes);

- hot water boilers (at the choice of the Customer or offered by TPK "Teploterm");

- automation of boilers and boiler room, instrumentation;

- pumping equipment (network and circulation pumps, make-up pumps, VPU pump);

- water treatment plant, taking into account the analysis of the customer's source water;

- household premises (operator's cabin, bathroom, etc. on an additional order);

- heating and ventilation system of the boiler room;

- flue pipe and other auxiliary equipment for reliable operation.

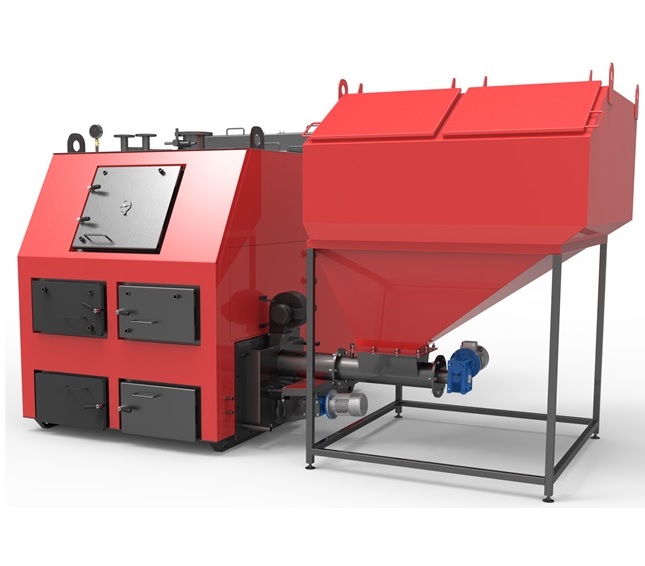

Description of the boiler room : In the boiler room it is proposed to install a Retra-4M 500 kW hot water boiler (Ukraine) with automatic fuel supply (fuel reserve bunker, automatic screw feed). Description of the boiler: Combined solid fuel boiler "Retra-4M Duo" is adapted to work in two modes:

|  |

In the first operating mode of the boiler , fuel (pellet) is loaded automatically from the bunker by a screw screw driven by a geared motor to the pellet burner. The most efficient combustion of fuel in a pellet burner is ensured by air blowing, which is carried out by a fan. The operation of the screw conveyor and fan is controlled by a microprocessor temperature controller. In the second mode, the loading of fuel (wood, coal) occurs through the loading hatch. The process of efficient combustion of fuel in the furnace is carried out due to the intensive supply of air around the perimeter of the chamber. This forms an "air cocoon" around the fuel. The gas that did not burn in the furnace due to lack of air burns out due to the supply of secondary air. This ensures a high efficiency. Advantages:

The principle of operation of boiler automation During and after automatic loading of the required portion of fuel into the burner, the fan intensively pumps air for a specified time to achieve a stable combustion temperature. This cycle is repeated until the water temperature in the boiler rises to the base values set on the thermostat. After that, the automation goes into the mode of maintaining combustion. When the temperature drops to a predetermined minimum level (recommended: 40-45 °C), fuel is automatically loaded from the bunker again and the fan is turned on and the boiler operation cycle is repeated again. If the temperature reaches the specified maximum level (recommended: 85-90 °C), the automation switches off the fuel supply, the fan and switches to the support state. Also, the thermostat is able to control the operation of the central heating pump in accordance with the specified parameters. | |

| The preparation of the source water for feeding the boilers is carried out using mechanical water purification filters mounted in the boiler room, after which the water is softened by passing through a Na-cationite filter (the filter body is made of durable glass fiber, which eliminates corrosion), which operates in automatic mode and requires only backfilling salts for the regeneration of the cation exchanger. After softening, water is supplied to fill the heating system with the help of multistage make-up pumps Wilo (Germany). |  |

| Pipeline fittings , adjustable and unregulated, are offered: for water - up to Du-40 - ValTec fittings or analogues, over Du-40 - Zetkama butterfly valves or analogues - increasing reliability without compromising the overall cost of the boiler house. All pipelines of the boiler house with a surface temperature above 55 ° C are covered with heat-insulating material. |  |

Thermal unit of the DHW system. The boiler room can be provided with a thermal unit of the DHW system (not included in the price) for heating water for household needs, consisting of:

|  |

| The pumping group of the boiler house includes a working and standby pump Wilo (Germany). To supply return water to the boilers at a temperature of at least 60 ° C, the boiler is provided with a recirculation pump Wilo (Germany). To compensate for thermal expansions, membrane tanks Zilmet (Italy) are installed in the boiler room . |  |

The boiler room provides for accounting for consumed water and electricity. Waste heat metering unit based on Ultraheat Landys+Gyr flow meter (Germany). |  |

The metal structure of the boiler house is a room made of metal panels with thermal insulation inside them, consisting of two separate modules (blocks). After installation, the boiler room is a single room with dimensions (LxWxH) 8350x6380x3450mm. On the walls of the modules there are doors that open outwards. There are also windows on the end and side walls of the modules. Window and door openings provide the necessary area for easily dumped structures. |  |

The chimney of the boiler room must be made of stainless steel with insulation, as flue gas condensate is very corrosive. The cost of the chimney is determined after the completion of the EIA project, as well as taking into account the location (attachment to the existing building, free-standing chimney in the frame, chimney material). |  |

For a more detailed calculation of the cost of MTCU, please download and fill out

questionnaire for hot water boiler

|