Pump station Pedrollo HF JSWm

| Наименование | Краткая информация | Артикул | Price | Qty | Add to Cart |

|---|---|---|---|---|---|

| Pump station Pedrollo HF JSWm 1BX/24-CL | Capacity: 0.3 - 3.0 m³/h Head: 36.0 - 15.0 m. Art. Power: 0.50 kW | HFS1BX24 |

₴0.00

|

||

| Pump station Pedrollo HF JSWm 1AX/24-CL | Capacity: 0.3 - 3.0 m³/h Head: 42.0 - 19.0 m. Art. Power: 0.60 kW | HFS1AX24 |

₴0.00

|

||

| Pump station Pedrollo HF JSWm 1CX/24-CL | Capacity: 0.3 - 3.0 m³/h Head: 32.0 - 13.0 m. Art. Power: 0.37 kW | HFS1CX24 |

₴0.00

|

||

| Pump station Pedrollo HF JSWm 2CX/24-CL | Capacity: 0.3 - 4.2 m³/h Head: 47.0 - 20.0 m. Art. Power: 0.75 kW | HFS2CX24 |

₴0.00

|

||

| Pump station Pedrollo HF JSWm 2AX/24-CL | Capacity: 0.3 - 4.2 m³/h Head: 55.0 - 28.0 m. Art. Power: 1.1 kW | HFS2AX24 |

₴0.00

|

Pump station Pedrollo HF JSWm

Pedrollo pumping stations are designed for water supply to summer cottages, cottages, and other domestic and industrial premises. Automatically maintain water pressure. They consist of a pump, a hydraulic accumulator, connecting fittings, pressure and a pressure gauge for pressure control. The source for water intake is: a well, a well, a container or a central water supply.

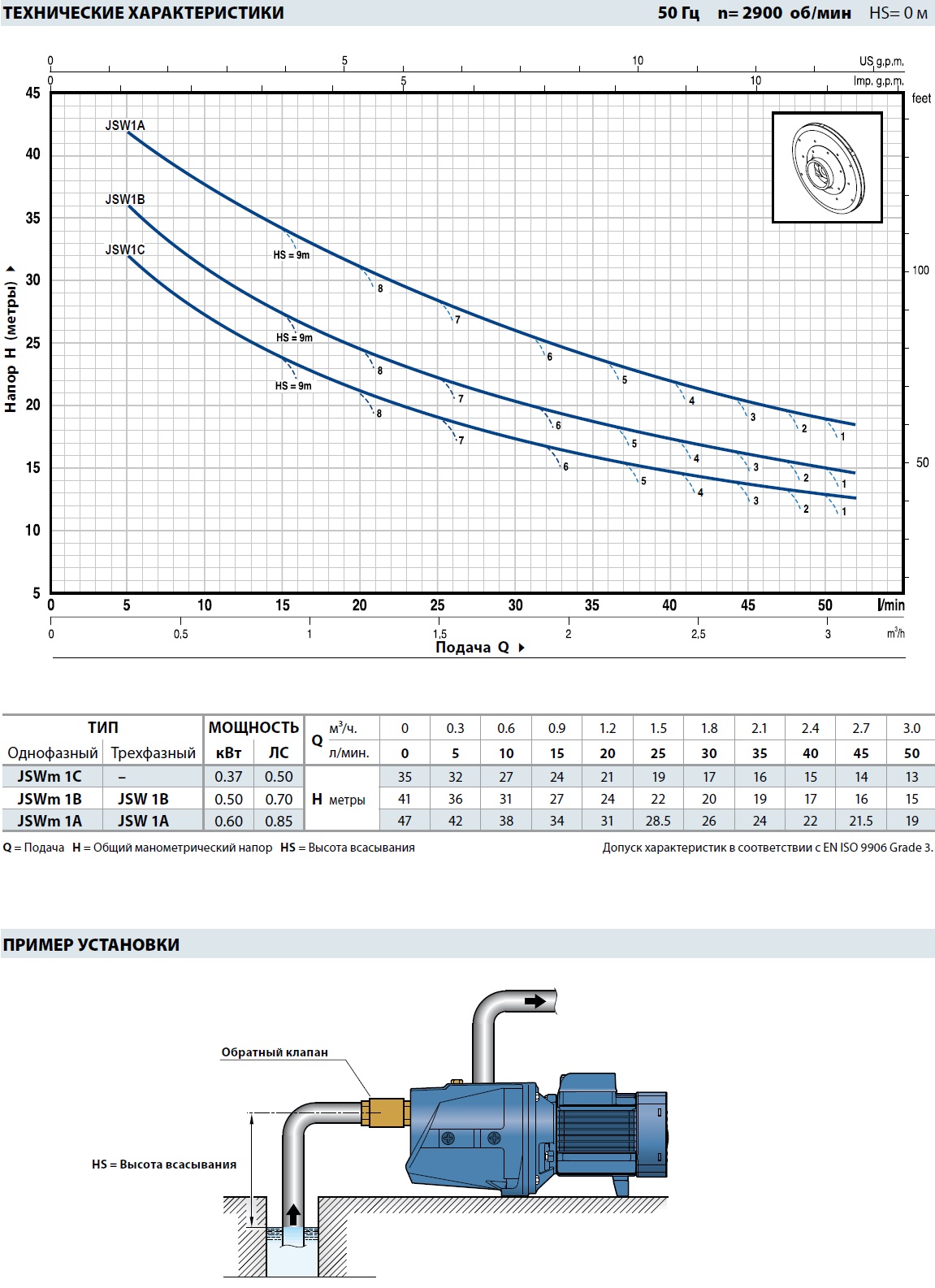

Brief technical characteristics of the Pedrollo pumping station

- manometric suction lift up to 9 m

- liquid temperature up to +40°C

- maximum ambient temperature +40°С

Principle of operation

The Pedrollo pumping station of the JSW series includes self-priming centrifugal electric pumps.

The self-priming effect is achieved thanks to the ejector installed in the pump housing. Only a part of the total feed generated by the impeller of the closed centrifugal tone is sent to the discharge pipe; the rest is recirculated by means of an ejector, which, being connected to the suction chamber, creates in it the vacuum necessary for self-priming.

At the first start, it is enough to fill the pump housing with water; it is not necessary to fill the suction pipe and remove any air pockets that may be present. At the moment of start-up, the water contained in the housing, circulating through the ejector, will move the air from the suction chamber to the discharge chamber, pushing it through the discharge pipeline. At the same time, the vacuum created in this way will cause the water level in the suction pipe to rise, thereby causing self-priming. The constant operation of the self-priming system makes such pumps practically insensitive to the presence (even significant) of dissolved air in the liquid being pumped.

Scope and installation

Pumping stations of this series are recommended for pumping clean water and chemically non-aggressive liquids. Due to their reliability, ease of operation and cost-effectiveness, these pumping stations can be successfully used in everyday life, in particular, for automatic water supply in conjunction with small and medium-sized hydraulic accumulators, for irrigating vegetable gardens, orchards, etc. The installation of the pumping station must be carried out indoors or in places protected from the weather.

Structural features

- Pump body made of cast iron, equipped with suction and discharge connections with pipe thread gas UNI 338, as well as side threaded holes for attaching a pressure gauge and pressure switch. AISI 304 stainless steel housing cover on which the mechanical seal is mounted.

- Ejector assembly in Noryl GFN2V "General Electric" technopolymer (certified for potable water). Impeller radial, centrifugal type, in Noryl GFN2V "General Electric" technopolymer or brass on request (certified for potable water).

- Drive shaft in AISI 416 stainless steel.

- Mechanical seal made of ceramic and graphite.

- The electric motor of the pumps is directly connected to a PEDROLLO electric motor of the appropriate power.

- The motor is asynchronous, high-performance, silent, closed type with external ventilation, suitable for continuous operation.

- Insulation class B.

- Single-phase motors have a built-in thermal protection device (emergency switch).

- Three-phase motors must be equipped with an appropriate external emergency switch, connected in accordance with current regulations.

- Degree of protection IP 44.

- Execution and safety regulations in accordance with EN60 335-1 (IEC 335-1, CEI 61-50) IEC 34 standards.

- The characteristics of the curves in the table have tolerances according to ISO 2548.

JSWm 1

|

JSWm 2

|