Fecal pump Pedrollo ZXm 1A/40

Availability: In stock

Fecal pump Pedrollo ZXm 1A/40

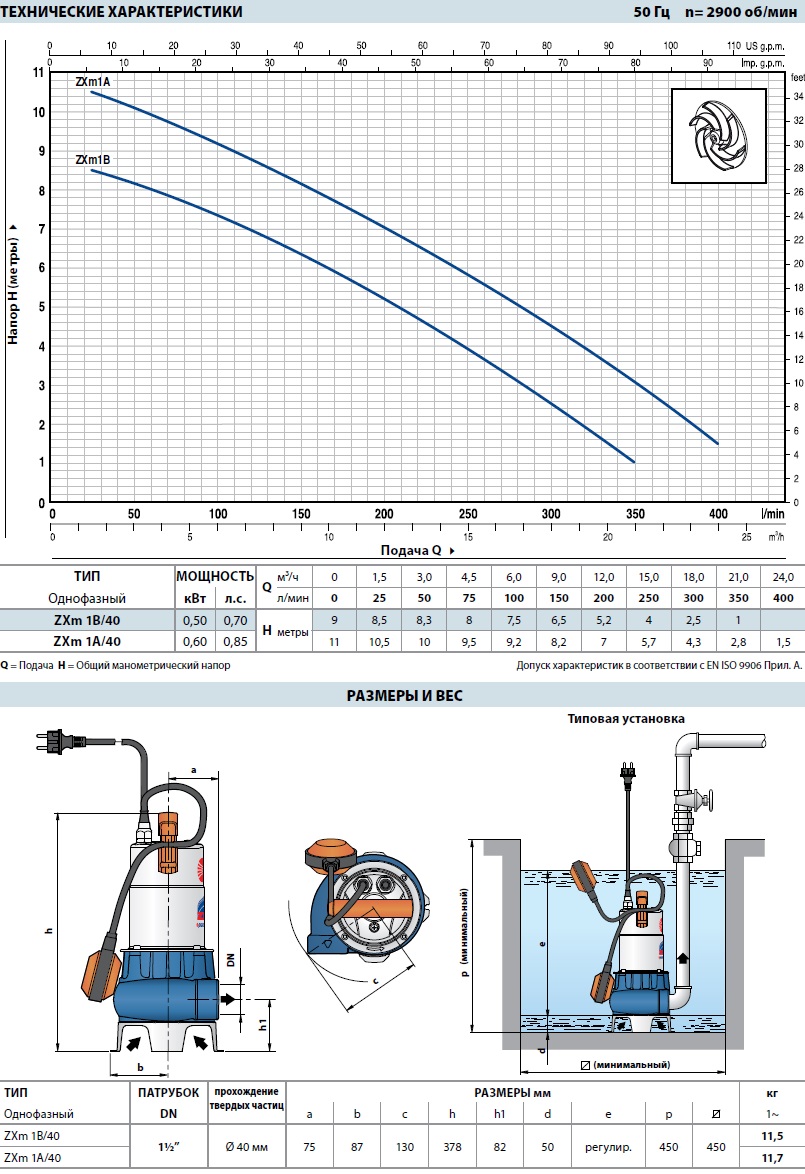

Brief technical characteristics

- body - stainless steel / cast iron, wheel - polymer

- flow up to 400 l/min.

- head up to 10.5 m

- maximum application depth up to 5 m below water level

- liquid temperature up to + 40°C

- maximum passage of suspended solids up to 35 mm

- maximum emptying level up to 40 mm from the bottom

Principle of operation

The ZX series includes submersible electric wastewater pumps designed primarily for domestic use. The principle of operation is similar to the principle of operation of centrifugal pumps with retracted impeller type "VORTEX". A spacious annular chamber, equipped with a discharge pipe with a pipe thread, is provided in the pump housing and is closed by a lid equipped with a supply pipe; which, thanks to its special shape, prevents possible oversized solid particles from entering the pump. Since the impeller is retracted relative to the cover, an end chamber is formed between them, in which the suction water acquires a vortex motion and, under the action of centrifugal force, is directed to the annular chamber, through which it leaves the pump through the discharge pipe.

Scope and installation

Pumps of this series are designed for lifting wastewater and chemically non-aggressive liquids. Due to their design features, these pumps are particularly suitable for domestic use, as well as in all cases where solid particles in suspension can be present in the pumped liquid, up to 35 mm in size. Thus, their use is recommended not only for draining flooded areas, such as basements and boxes, but also for pumping domestic wastewater, sewer drains, sewage with a high content of fibrous bodies. These pumps are characterized by extreme ease of installation and maximum reliability when installed permanently for automatic operation.

Stationary installation of the pump is possible inside wells with minimum recommended dimensions of 450x450x450 mm, to ensure complete emptying and normal functioning of the automatic start/stop float system. This setting allows the automatic start of the electric pump when a regulated level is reached and its stop after emptying. Installing an appropriate non-return valve in the discharge piping avoids liquid backflow during pump shutdown.

Structural characteristics:

- Discharge body made of cast iron, equipped with a 11/2" discharge connection with gas UNI 338 pipe thread.

- AISI 304 stainless steel engine jacket.

- Suction cover in AISI 304 stainless steel.

- Working cup of open type, made of GELON BA 6 technopolymer "General Electric®."

- Drive shaft in AISI 416 stainless steel.

- Carbon/aluminum mechanical seal.

- Motor: in oil bath, inductive, closed type, suitable for continuous operation,

- with built-in thermal protection device (emergency switch). Insulation class B.

- Degree of protection IP 68.

- Submersible power cable made of neoprene "H07-RN-F".

- Standard equipment 5 m with SCHUKO plug (on request 10 m).

- Execution and safety rules in accordance with EN60 335-1 (IEC 335-1, CEI 61-50) IEC 34 standards.

- The characteristics of the curves in the table have tolerances according to ISO 2548

|