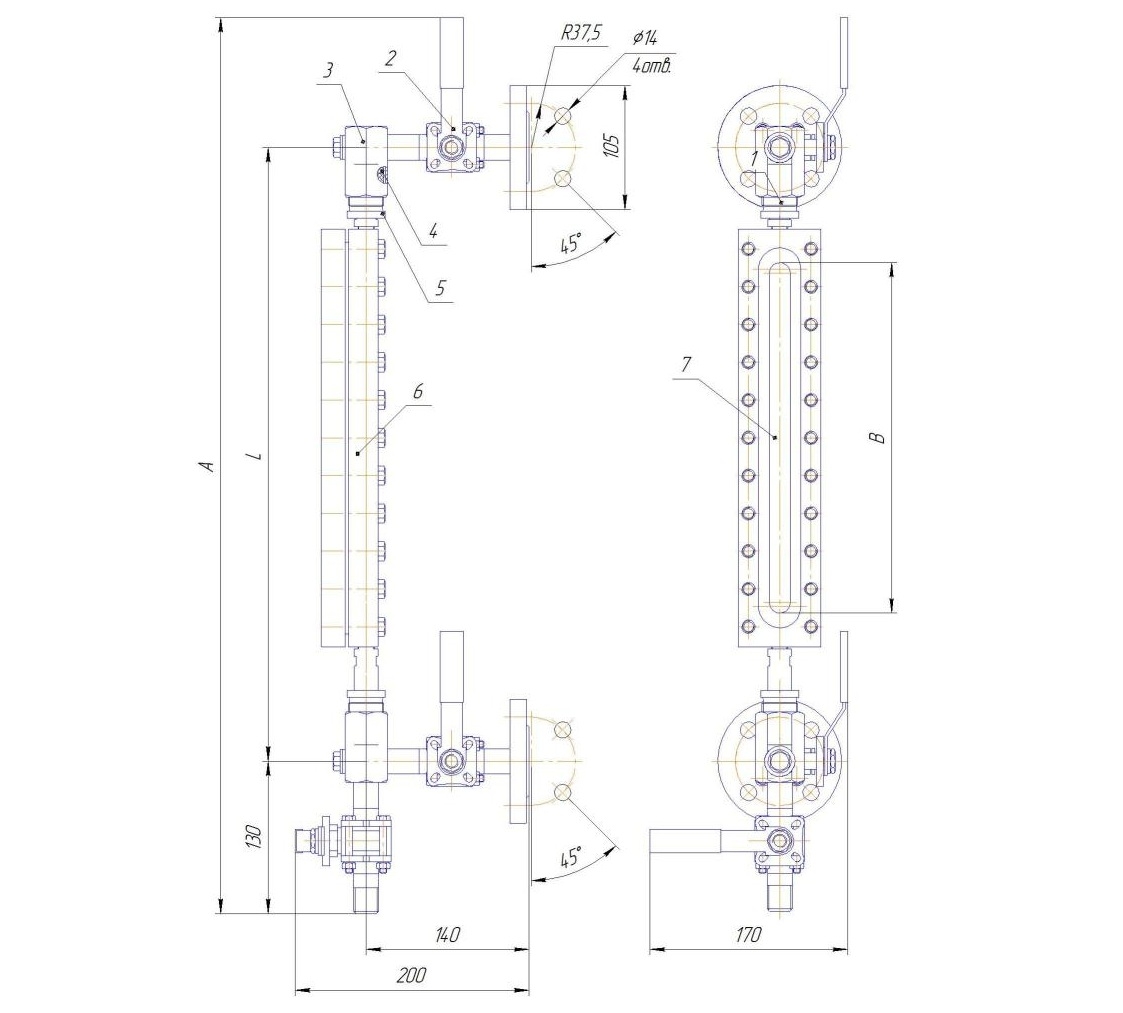

Liquid level indicator (frames No. 2 - No. 9) art.16.113

The pointer is made to order (7-10 working days)

Wafer distance: 320 - 540 mm

Working temperature , no more: 200 °С

Working pressure, no more than: 13 bar

| Наименование | Краткая информация | Артикул | Price | Qty | Add to Cart |

|---|---|---|---|---|---|

| Liquid level indicator (frame No. 2) art.16.113-2 |

The pointer is made to order (7-10 working days) |

16.113-2 |

$0.02

|

||

| Liquid level indicator (frame No. 3) art.16.113-3 |

The pointer is made to order (7-10 working days) |

16.113-3 |

$0.02

|

||

| Liquid level indicator (frame No. 4) art.16.113-4 |

The pointer is made to order (7-10 working days) |

16.113-4 |

$0.02

|

||

| Liquid level indicator (frame No. 5) art.16.113-5 |

The pointer is made to order (7-10 working days) |

16.113-5 |

$0.02

|

||

| Liquid level indicator (frame No. 6) art.16.113-6 |

The pointer is made to order (7-10 working days) |

16.113-6 |

$0.02

|

||

| Liquid level indicator (frame No. 7) art.16.113-7 |

The pointer is made to order (7-10 working days) |

16.113-7 |

$0.02

|

||

| Liquid level indicator (frame No. 8) art.16.113-8 |

The pointer is made to order (7-10 working days) |

16.113-8 |

$0.02

|

||

| Liquid level indicator (frame No. 9) art.16.113-9 |

The pointer is made to order (7-10 working days) |

16.113-9 |

$0.02

|

Liquid level indicator with welded stopcocks (frames No. 2 - No. 9) art.16.113

Level indicators art.16.113 have proven themselves well on steam boilers:

- DE series;

- DKVR series ;

- KE series ;

- Viessmann;

- Buderus;

Also, level indicators art.16.113 are installed on other steam boilers, condensate tanks and water storage tanks.

Characteristics

Center distance between flanges: from 320 to 540 mm.

Working medium - water, water vapor, condensate with pH = 9.5 - 10.5.

Working temperature, no more than - 200 °C .

Nominal pressure: 16 bar

Working pressure, no more than: 13 bar

materials

| pos. no. | the name of detail | Qty | Material |

| one | Flange Du20, Ru16 | 2 | Steel 3 |

| 2 | Stainless steel ball valve art.2011 | 3 | Stainless steel |

| 3 | Locking device housing | one | Steel 09G2S |

| four | Sealing ring | four | Graphite |

| 5 | clamp nut | 2 | Steel 09G2S |

| 6 | Level indicator frame art.25.117 | one | Steel 09G2S |

| 7 | Corrugated glass with paronite gaskets | one | Glass / paronite |

Drawing of the level indicator art.16.113 |

Connecting and overall dimensions of level indicators art.16.113

| Frame No. | Glass size, mm | L,mm* | Ah, mm | V, mm | C, mm ** | D,mm | Weight, kg |

| 2 | 140*34*17 | 320 | 580 | 117 |

105 |

37.5 | 7.9 |

| 3 | 160*34*17 | 360 | 620 | 137 | 8.6 | ||

| four | 190*34*17 | 390 | 650 | 167 | 9.2 | ||

| 5 | 220*34*17 | 420 | 680 | 197 | 9.8 | ||

| 6 | 250*34*17 | 455 | 715 | 227 | 10.5 | ||

| 7 | 280*34*17 | 490 | 750 | 257 | 11.0 | ||

| eight | 320*34*17 | 520 | 780 | 297 | 11.4 | ||

| 9 | 340*34*17 | 540 | 800 | 317 | 12.0 |

* - interaxal dimension L can be changed when ordering.

** - the size of the connecting flange 105mm can be changed when ordering.

Attention! When ordering a level indicator, you must specify its full designation:

Level gauge with threaded stopcocks art.16.113-No.-L-** , where:

1) Level indicator with welded shut-off valves - product name;

2) Art.16.113 - article number of the product;

3) № - index frame number;

4) L - distance between the axes of the connecting flanges in millimeters;

5) ** - the size of the connecting flange is indicated if its size differs from the standard one (105 mm).

If possible, the operating medium, pressure and temperature should also be specified.